MINGMEN mute door locks,Follow the trend of door locks and manufacture high quality products with high technology. In 2015, Mingmen silent door locks started the intelligent upgrade of manufacturing, and the current annual production capacity has reached 3 million.

Industry 3.0Era |

| Annual production capacity 3millionTen thousand |

Mingmen uses ABB robots to integrate the manual and disorderly polishing actions into a standard operation of a piece of equipment, changing the traditional manual operation mode and shortening the cycle from 7 days to 1 day.

The one-time pass rate has been increased to 99.5%, and the quality has reached the highest level in Italy and Germany, which can replace imported products.

Mingmen optimizes the mold (fixture) design, adopts the intelligent constant temperature distribution system of the central furnace, introduces manipulators and automation equipment, changes the traditional operation mode, and upgrades to single-piece flow production. In the past, 12 people gathered into one person to complete the work, realizing automation and standardized operations; the one-time pass rate increased from 99% to 99.5%, and the production cycle was shortened from 5 days to 1 day.

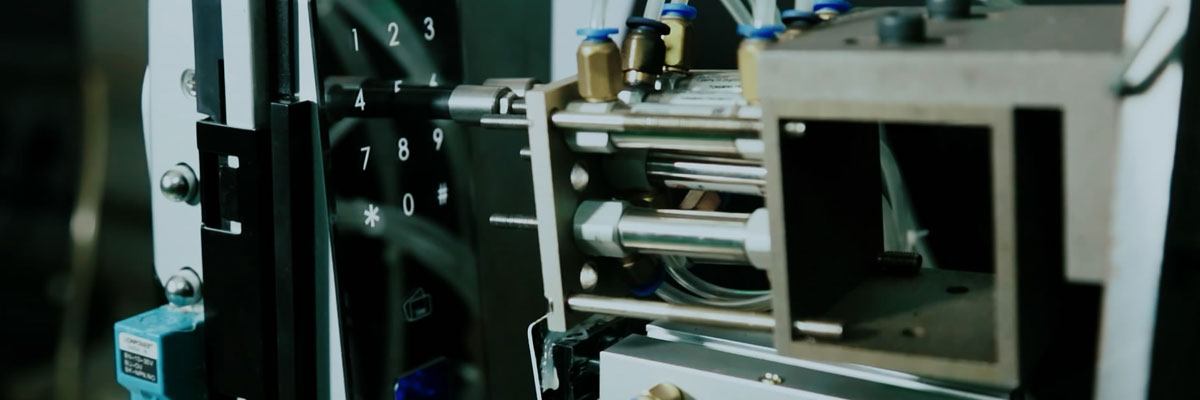

The clutch is the core component of the lock body, which is responsible for the linkage of the internal mechanical structure. Before each clutch goes online, it will conduct 1000 switch simulation tests to ensure zero defects in the online materials.

After the aging rack is powered on, the program automates the simulation test and performs aging on all circuit boards. The aging room is equipped with a temperature control system, which is rare in the industry. 100% of the electronic suite undergoes a 48-hour aging test; 100% of the electronic suite undergoes a full-featured test after aging.

After the lock body is assembled, 100% full function inspection is simulated in the user's use scenario; a good working environment and quality awareness ensure the excellent quality of the product and prevent faulty locks from entering the market.

In 2005, Mingmen established a quality inspection center. The perfect quality control system promoted Mingmen to become the "leader unit for drafting national and industry standards in the lock making industry". More than 30 enterprise standards were drafted and filed in Zhongshan Quality Supervision Bureau.

Industry-leading testing equipment, including electroplating layer thickness tester, laser density time measuring instrument, EZ fingerprint lock durability testing machine, handle opening durability testing machine, ultraviolet accelerated weathering testing machine, constant temperature and humidity testing machine, etc., a total of more than 60 tower.

The tireless testing process and the testing standards of famous enterprises, on the basis of covering and exceeding the national standards, combined with the user's use environment and actual experience, have filled a number of national standard gaps. For example, there are only 37 national standards for mechanical locks, and Mingmen has independently added 37 enterprise testing standards; there are 74 national standards for fingerprint locks, and Mingmen has independently added 48 items. The lock body has undergone a life test of 200,000 times, and the door can be opened and closed 20 times a day on average, and it can be used for 27 years. Everything we do is for the user's quiet life experience.

Mechanical lock 37+ 37National standard + enterprise standard |

| Fingerprint lock 74+ 48National standard + enterprise standard |

| Life testing 200000+ |

In 2015, the company invested millions of dollars. It was built by the Fifth Electronics Research Institute of the Ministry of Industry and Information Technology (CEPREI) and built a semi-anechoic laboratory. The background noise of the laboratory is 16.9d B(A), 18.6 Hz.

In 2018, Mingmen standard products will achieve a 7-day production cycle, far exceeding the industry average cycle of 30 days, and achieve a one-time pass rate of 99.5%.

At the same time, the customized flexible production system realizes the personalized customization of colors and functional modules.

With the continuous investment in MES and CRM in the automation of Mingmen, the industrial system of Mingmen is moving towards the era of Industry 3.0.

As the leading enterprise of silent door locks in China, Mingmen silent door locks have excellent quality and production level, bringing users a high-quality silent life experience.